Technology

Experience YHY’s cutting-edge R&D and production technology, showcasing our expertise in VR motion simulators through advanced product design, mechanical analysis, software development, and rigorous quality control.

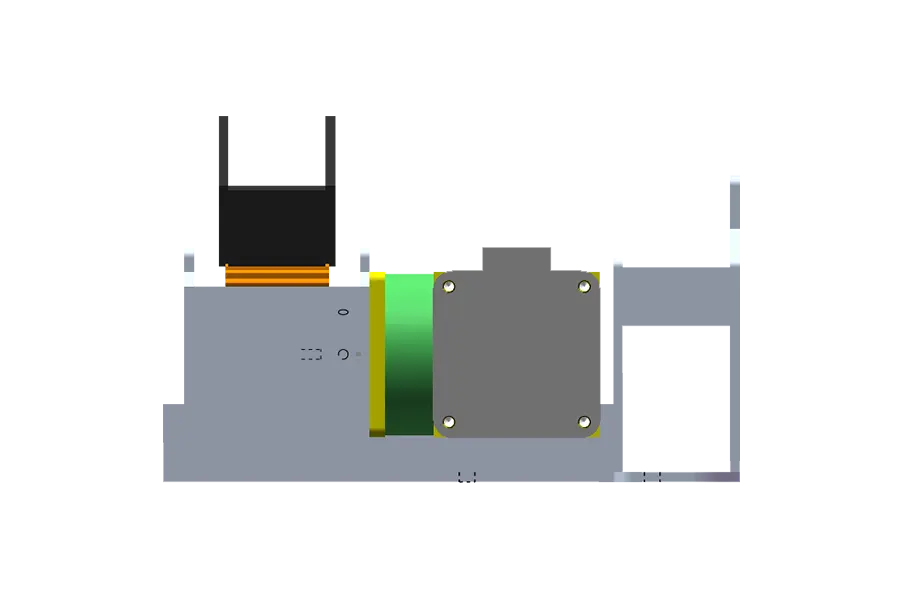

YHY's New 3 DOF Motion Platform Exclusive Technology

Self-developed control system and motion algorithm provide accurate feedback of every movement detail,eliminating the problem of dizziness.

Adopt a new type of circular arc structure movement trajectory, which has a larger movement range than the traditional motion plalform.

The extremely small footprint creates unlimited value.

Have an independent flm content development team, constantly update, and can customize the content according to customer needs.

1

1

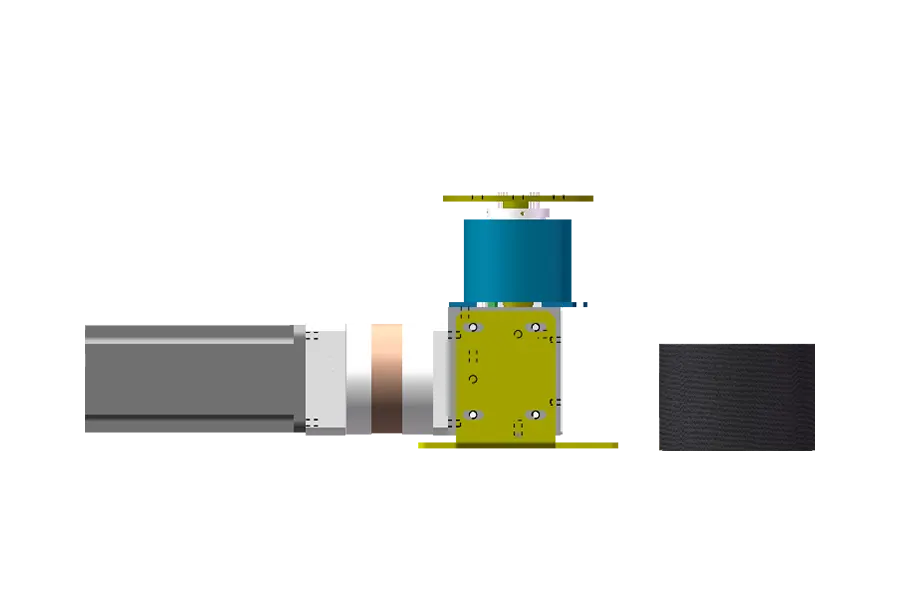

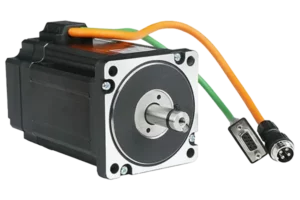

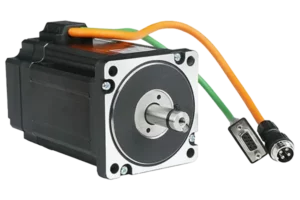

Drive motor

- Low noise

- Low energy consumption

- Low temperature rise

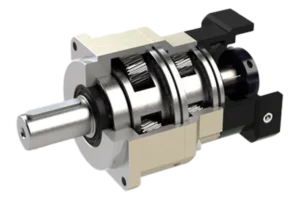

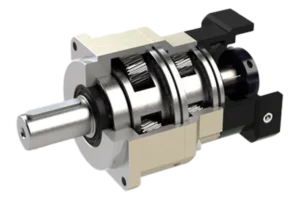

Planetary reducer

- Low noise, low backlash, high efficiency

- High input speed, high torque

- High stability, high speed ratio

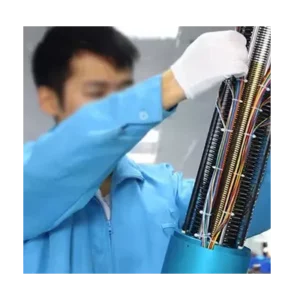

Conductive slip ring

Conductive slip ring

- Integrated structural design

- Adopting advanced precious metal cluster brush multi-point contact to ensure reliable contact under extremely low friction.

Chassis part

4

4

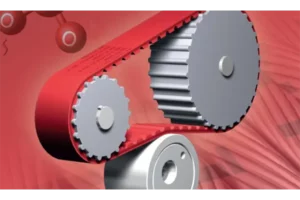

Synchronous wheel

- Accurate transmission, no slip during operation, with a constant transmission ratio.

- Smooth transmission, with buffering, shock absorption and low noise.

- High transmission efficiency, up to 98% or more, with significant energy saving effect.

Synchronous belt

- Cast polyurethane synchronous belt, the pitch accuracy ofthe entire belt is high

- Made ofwear-resistant polyurethane and a high-strengthsteel wire tensile layer, it has an extremely low elongationrate and is highly durable

- Resistant to tropical climates, grease and gasoline, andcertain acids and alkalis

Planetary reducer

- Low noise, low backlash, high efficiency

- High input speed, high torque

- High stability, high speed ratio

Drive motor

- Low noise

- Low energy consumption

- Low temperature rise

Upper part

YHY Exclusive 3-DOF Motion Platform

Comfort

Excitement

Noise

Failure Rate

Bear Loading

General 3-DOF Motion Platform

Comfort

Excitement

Noise

Failure Rate

Bear Loading

Technology Advantages

Independent Development

Raw Material Advantages

Research Focus Areas

YHY focuses on equipment updates, software enhancements, and game expansions to boost business competitiveness. Our innovation ensures clients receive cutting-edge technology, improved user experiences, and sustainable growth in the VR market.

Equipment Updates

We are continuously improving the hardware components of our VR simulators to enhance performance and user experience.

Software Enhancements

YHY develops and refine our proprietary software to ensure smooth operation and seamless integration with our hardware.

In-House Game Development

YHY's in-house game development team creates custom games tailored to optimize the immersive experience of our motion simulators.

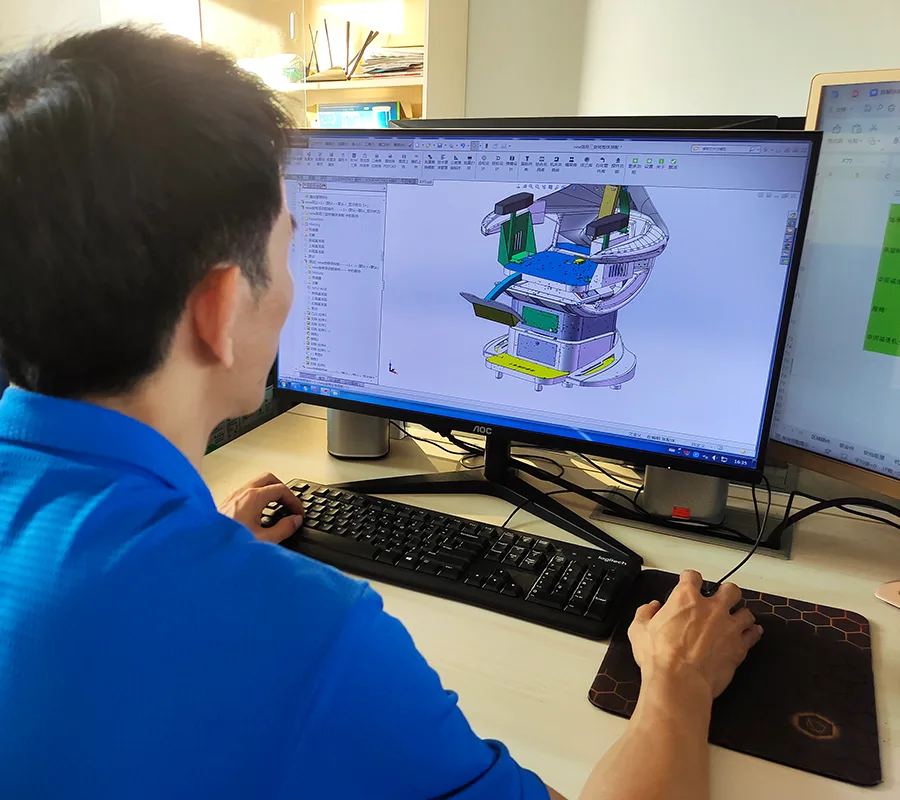

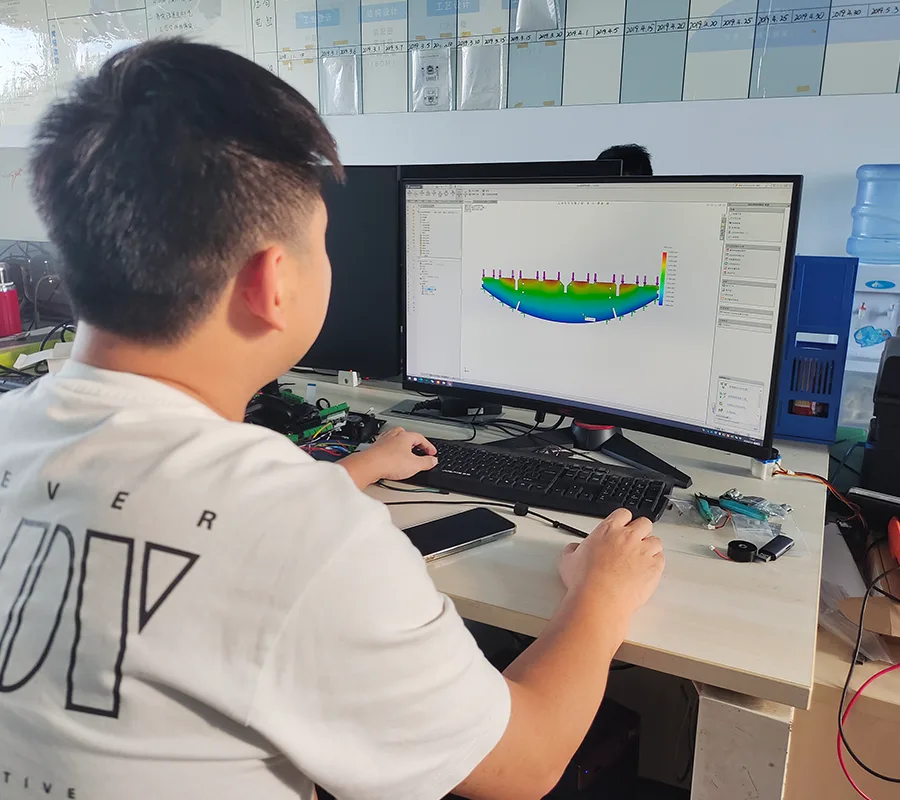

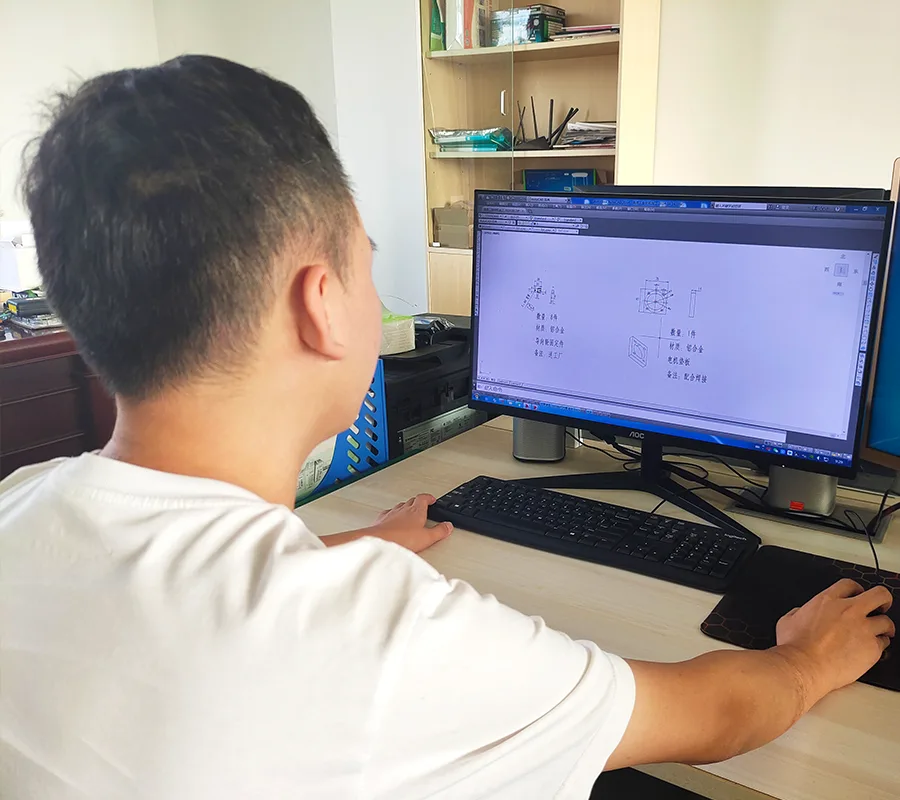

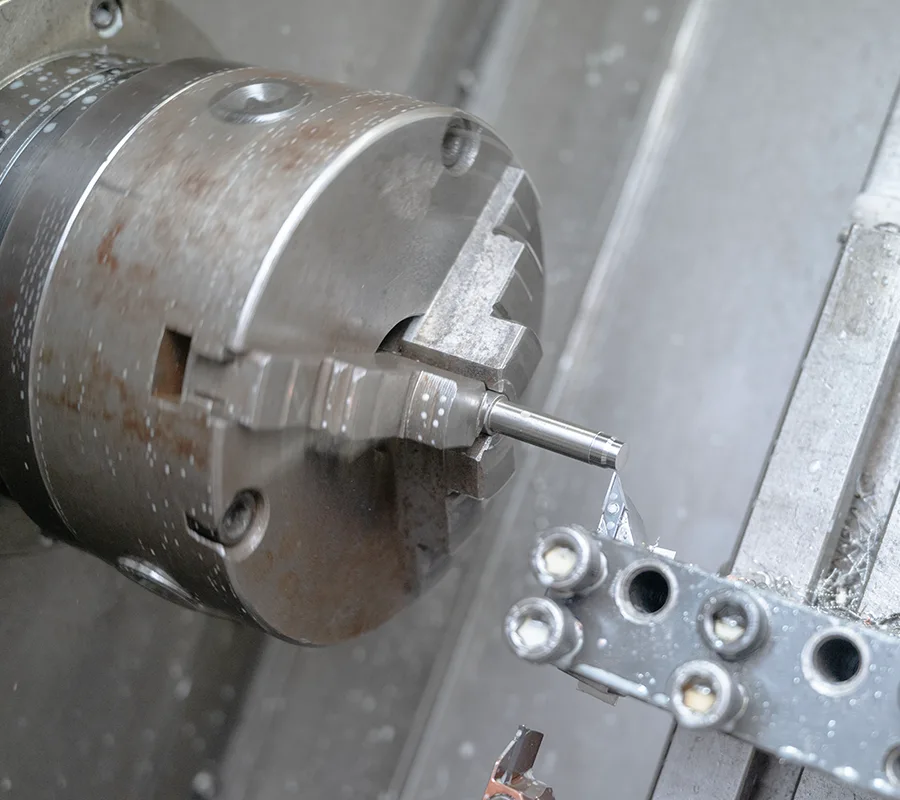

Product Design and Development Process

Our meticulous design and development process ensures the highest standards of quality and innovation.

1. Product Design:

2. Mechanical Analysis:

3. Drawing Review:

4. Component Processing:

5. Component Assembly:

6. Equipment Debugging:

7. Finished Product Testing:

8. Packaging:

9. Shipping:

State-of-the-Art Manufacturing

Discover how our advanced production techniques ensure high-quality VR simulators tailored to meet the demands of the entertainment industry.

Workshops

Machines

Craftworks

Quality Control

At YHY, we are committed to delivering the safest and most reliable VR simulators in the industry. Our rigorous quality control process encompasses every stage of production, from component sourcing to after-sales support.

- Component Inspection: We meticulously inspect all parts and components, ensuring they meet our high standards before assembly.

- Semi-Finished Product Testing: Each semi-finished component undergoes thorough testing to verify functionality and quality.

- Assembly Process Monitoring: Our skilled technicians closely monitor the assembly process, adhering to strict quality guidelines.

- Operational Testing: Every finished product undergoes extensive operational testing to ensure optimal performance.

- Pressure Resistance Testing: We conduct rigorous pressure tests to guarantee the durability and safety of our simulators.